Process engineering and sustainability. Companies change their DNA for the 21st century.

For millions of companies an awareness of resources, people and the environment has taken on new importance. Demanded by institutions, strategic partners and customers, how can sustainability actually be put into practice? Here are some guidelines to designing in a sustainable way.

For some time process engineering has had to contend with what has become a key requirement for anyone in business: sustainability. Naturally, the term refers to human, economic and productive resources, but also, increasingly, to the environment.

In 1987, the World Commission on Environment and Development’s Brundtland Report came up with a definition of "sustainable development" that is still used globally today: “Development that meets the needs of the present without compromising the ability of future generations to meet their own needs”.

For us at STAR7 it’s an apt reminder, because our own approach is based on exactly the same principles: the ability to help lay the foundations for a balanced present and a positive future – for us and our customers.

But how do you turn such high and noble aspirations into an actual ecosystem of data, technology, people and relationships?

Life Cycle Thinking: a holistic approach

Sustainability and social impact have to penetrate every aspect of a business’s DNA. They have to go from being a box to tick to a structural prerequisite.

In the field of process engineering, the key step in this regard is the transition from Life Cycle Assessment to Life Cycle Thinking. The latter encompasses and expands the former. ENEA (the Italian Agency for New Technologies, Energy and Sustainable Economic Development) captures this shift when it speaks of an approach "with which to analyse the environmental, economic and social sustainability of products, services, technologies and systems, considering all phases of the life cycle ([...] raw materials, production, use, distribution and end of life)". Using widely known tools such as Life Cycle Assessment, Life Cycle Costing and Social-LCA, and others specific to each business sector, we must begin to think in terms of degrees of separation, expanding supply chain boundaries and avoiding impact transfer between different parties (suppliers, customers), internal operating areas (non-core activities) and different environments.

A competitive advantage for Brand Reputation

The principles that guide and clarify the company mission and vision, or simply integrate it into the business, become: 360-degree thinking and design, circular economy, a focus on intangible production elements and forging new relationships (with experts, public authorities, partners, customers). Out of this flow new and compelling benefits. They range from the economic – the result of better, more considered and long-term choices – to the quality of life and work and the boost that this kind of paradigm gives to Brand Identity, Reputation and Customer Loyalty. In other words, a multi-pronged competitive advantage.

Continuous evolution

The unique nature and inherent challenge of this approach lies in never considering targets as definitive, but always merely as the best possible result at a particular time – not a formula set in stone. The method itself requires constant re-evaluation; during this continual work in progress only the vision of those who adopt it and take its principles and mechanisms to heart remains fixed. Evolve to adapt, and adapt to evolve, one might say.

The STAR7 approach to sustainable planning

This is the direction we have chosen for our STAR7 Engineering service line. We believed that only with a new "model", capable of uniting technology and people, could we propose a truly sustainable approach, in terms of time, costs and waste. We wanted a solution that prioritised information fluidity and avoided (for example) expensive prototyping linked to a process that may be well established but which doesn’t fully benefit from the digital revolution at the heart of the Group's services and technological approach.

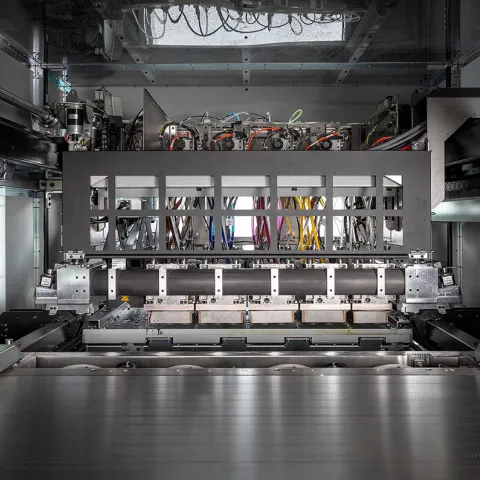

Content digitisation and the integrated management of processes to improve usability and bring added value to associated information mean it is possible to take a fresh look at the classic analysis path of the various processing phases. As a result, decisions are faster and more reliable. That includes those related to assessment traceability and the consequent changes made, as well as those related to general product improvements.

All this leads naturally to a significant time and cost advantage, but above all it drives a substantial reduction in dependency on physical objects to obtain, visualise and test solutions or situations. And by digitally reproducing all the evolutionary phases of a product, the result is, ultimately, also much more extensive and reliable.

Using this approach we have designed and developed E-suite, an ecosystem of tools, people and procedures that together represent the concrete application of Integrale⁷, the operating philosophy that has become the DNA of STAR7. E-suite consists of a set of complementary elements that constantly interact, sharing skills and data and perfectly balancing the human with the technological. And, to return to the issue in hand, our goal is to optimise projects’ sustainability, making sure each part of the whole can be viewed with complete operational clarity.

Our team of specialists comprise the mind of E-suite, with its technological soul provided by: Antares, an application that offers a modular, interactive and real-time 3D product presentation experience; Mizar, for immersive and predictive design and analysis, providing a hyper-realistic experience of the perceived quality of the product; and NSE, a platform created to organise, standardise, monitor and speed up the development of products and assembly lines for Manufacturing and Assembly design.

With E-suite, nothing is left to chance: everything is connected, everything co-exists, interacts and, naturally, evolves in a sustainable way.